Attenuation Pond Lining System for major Infrastructure Project

Our fabrication workshop team have started work on a 10 500m2 Attenuation Pond Lining system order today.

10 500m2 of both our HBB 300 protective Geotextile and Power Scrim 1000 Liner are being fabricated into pond specific sized pre-welded panels, and will be installed by our repeat clients installation team across four attenuation ponds.

By supplying pond specific sized pre-welded panels, the amount of onsite welding is massively reduced, which provides a very significant operational and efficiency advantage compared to welding every roll width onsite.

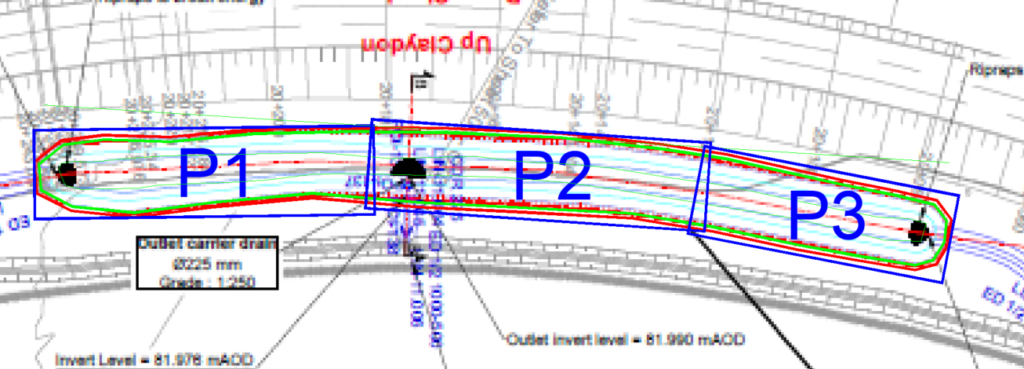

To ensure each panel is made to pond specific dimensions, we received 3D topographical surveys of each pond from our client, in turn we then formulated a pond specific sized panel plan for each pond, with the panel plan for Pond 1 shown below.

The panel plan details panel 1 (17m wide x 61m long) panel 2 (17m wide x 61m long) and panel 3 (17m wide x 47m long), meaning only 2 x 17m welds will be required on this 2656m2 pond.

If you require a pond lining system, please contact us, we have a range of liners available to meet your specific requirements. We would love to work on your next project with you.